Paper-based technology

Practical Action

Wheeled items

Thin card, thick paper, and sometimes carton card is used to make wheel assemblies consisting

of a bearing in which an axle with fitted wheels can rotate or a single wheel between two bearings,

and also to make steering systems for some items for people with disabilities. Bearings are usually

attached under a chassis. Wheeled items include toy cars and carts for pre-school, and much

sturdier items for people with disabilities including push chairs with insertable wheel systems,

floor rafts, push-along tricycles, self-propelling trolleys, and low-level wheelchairs. All these are

for clinical or home use rather than for rough use outside, but they are quite durable and easy to

repair.

Making a child‖s chair

This chair is a Utility model, using Approach II: two

vertical boards joined by a pattern of rails which

support a seatboard. It is not a difficult model, but

making it involves a number of operations. It is the

prototype of all Approach II Utility models. Some

preliminary knowledge is necessary, and as the chair

will be made in stages this knowledge will be

provided before the actual working instructions,

stage by stage.

Preparatory stage

Making the templates and the components

First: Get a clear idea of the job. Study the

illustration on page 20. Decide the exact size and

shape of the chair you want to make, and cut card

templates for the three boards. On the sideboard

templates mark where the holes for the tubes (rails)

will be, allowing for the top of the seatboard to

project slightly above the sideboards.

You need to know:

What grain/corrugation direction is. (See

earlier)

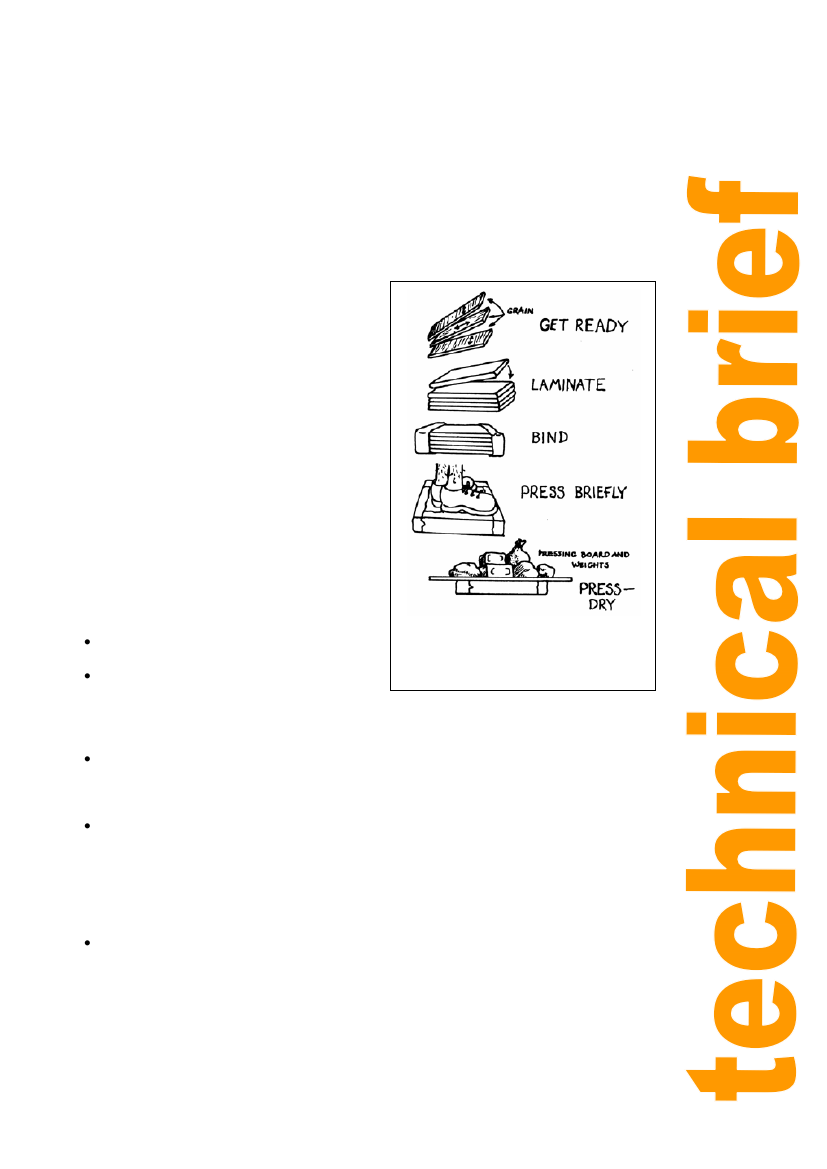

Figure 2: Laminating - work quickly,

race-the-stretch

How to make paste from plain flour. Follow

these instructions exactly: Mix a heaped

tablespoonful of plain flour in a little cold water, stirring until it is the consistency of

cream and there are no lumps. Pour in 500ml of boiling water, stirring vigorously and

continuing to stir for some time.

How to prepare your work surface. Spread a square of plastic on your table and place

either on it or nearby the following: a container of paste; a container of water; a sharp

knife; a plastic bag of pre-pasted strong paper (such as from a potato bag); some

newspaper; cutting and pressing boards; a rough stone; and weights.

How to laminate corrugated card to make boards. Decide from the thickness of the card

that you have how many layers will be needed to make a board about 150mm thick. Use

a template to cut each piece of card to the right sizes with grain direction alternating with

each piece. Place one card on your table plastic. Paste it generously all over. Place the

next card on it, with grain alternated. Paste that one. Continue until the board is over

150mm thick, with the template as the top layer. Wrap in a sheet of newspaper. Press it

first by treading all over it, then leave it pressed under a weighted board to dry.

How to roll tubes of thin card for the chair. Prepare rectangles of card which are about

40mm longer (along the grain) than the width of the seatboard. Find a suitable roller

(such as a broomstick). Lay the card on the table plastic, with its grain parallel to the

table edge. Smear paste thinly over the card and onto the roller. Place the roller along the

front edge of the card. Roll the card tightly onto it, and continue rolling it to stick the end

edge down. Seal it down with pasted paper and pull it off the roller without delay.

Get to work:

Laminate the boards, roll the tubes, and let them all dry.

4